Capabilities

The ultra-modern R&D,Production and Testing facilities used at Uniflow ensure the highest quality standard demanded by its customers. These facilities are committed to the continual development of our technologies. The company has modern manufacturing facility - in Chennai, in Tamil Nadu, India - that cover more than 10,000 sq.ft.

R&D

Product designs are created in a 3D environment leveraging state-of-the-art design, simulation and analysis software. In Uniflow all valves are designed, developed and prototype tested according to customer requirements as well as the international standards with design package and calculation. We perform our basic design considering process media, operating pressure and temperature by selecting appropriate materials.

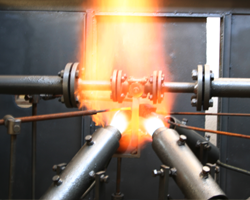

In-house Qualification Test Facilities

- High temperature high pressure test

- Cycle test

- Fire test

- Cryogenic test

- Vacuum test

Production Facilities

Uniflow manufactures a variety of Ball valves including large-sizes upto 24” and high-pressure valves upto 2500 class, as well as valves in exotic materials such as Monel Alloy 600, Hast alloy B&C, Alloy 20,Titanium in addition to low temperature carbon steels and austenitic stainless steel.

We are also geared for high-volume production of standard valves. Our processes ensure that the valves meet international standards as well as customer requirements.

Uniflow’s production processes take care of health, safety and environment protection and guarantees that it does not adversely impact our mother earth.

In-house Machining Facilities

- CNC Machining Centers

- CNC Vertical Turret Lathes

- Cranes with 40 ton capacity

- Ball finishing Machines

Testing Facilities

At the core of the functioning of Uniflow, lies a strong commitment towards quality. Utmost care is taken for guaranteeing quality at every step from stringent vendor qualification to final test of valves.

NDT methods are employed to qualify samples and pilot lots, and periodic audits are carried out to ensure compliance. Our PMI testing capability goes above and beyond standard industry procedures, proving the composition of valve materials and underpinning our quality assurance.

In-house Testing Facilities

- State-of-the-art Pressure Test Facilities

- PMI machine

- In-house Non-destructive Test Facilities & ASNT certified personnel

- Pressure Test Facilities

100% of the valves manufactured at Uniflow’s plant are pressure-tested. The acceptance criteria adopted are more stringent than the requirements specified in international standards.